Spectrum Packaging engineer and develop packages from the inside out.

Beer, wine, spirit & beverage products are our speciality and show off our packaging prowess, however we provide other product industry packaging and component packaging depending on which industry the packaging is required for.

Our innovative approach to premium gift box and cardboard box development is given the same high attention to quality regardless of the package or industry – utilising our unique in house Technical Innovation Management (T.I.M.) dynamic software program. The development program incorporates package engineering, digital technology with graphic design compatibility specifically developed for packaging.

The Technical Innovation Management (T.I.M.) software program is the brainchild of our dedicated and passionate team of packaging specialists. The program has been developed to deliver from concept to finished product.

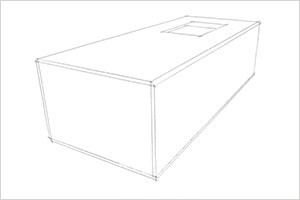

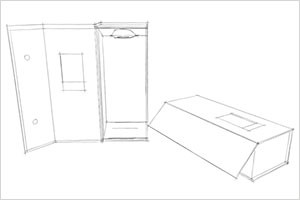

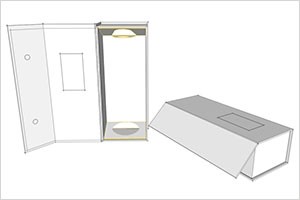

Working with various combinations of the T.I.M. program allows our team to incorporate the many facets of the packaging creation and development process. Combining design aspects, engineering and construction components, 3D modelling and photographic elements to develop on screen “virtual packages”.

The 3 dimensional modelling screen images of the packaging concept provides a valuable tool in packaging development process – a significant visual guide for the decision makers when developing a package from concept (or brief) to final print and production process.

Our T.I.M development software provides graphic designers, clients, marketing departments and packaging development personnel with a effective tool for evaluating the package and product look, at a relatively early stage of development.

In addition, our virtual 3 dimensional models can be decorated with logos and design graphics for that ultimate virtual package presentation and product evaluation.†

From these virtual computer screen images we can further develop the packages with construction elements in mind and review dimensions, creases, folds, box function, assembly, to further understand the practical applications.

This provides a multi aspect evaluation and review of the package look, dimensions and its construction components.

The XO Brandy Gift pack and the Yellowtail Anniversary gift boxes are just two examples of premium single bottle gift boxes that were fully developed utilising our Technical Innovation Management program. Multiple product packages are also available.

Our large format artwork proofing system allows us to print full size “Printers Proofs” for finished art evaluation and greatly assists final artwork specifications and approval process. All graphic components (Logo’s, text, fonts, colours etc.) image positions and mandatory specifications can be viewed, checked and approved at actual size prior to printing. Our Barcode scanning equipment verifies the number and provides confirmation that the barcode image scans.

We also offer the option of Production Proof – a fully printed and decorated gift box or wine box produced to dimension and print specification. This option allows final evaluation of a finished printed product prior to volume production schedule and also allows for final component testing opportunities such as packing and transportation.

† Subject to compatibility: Technical Innovation Management program requires Graphic design, Artwork, logos, etc to be supplied in suitable, compatible formats.